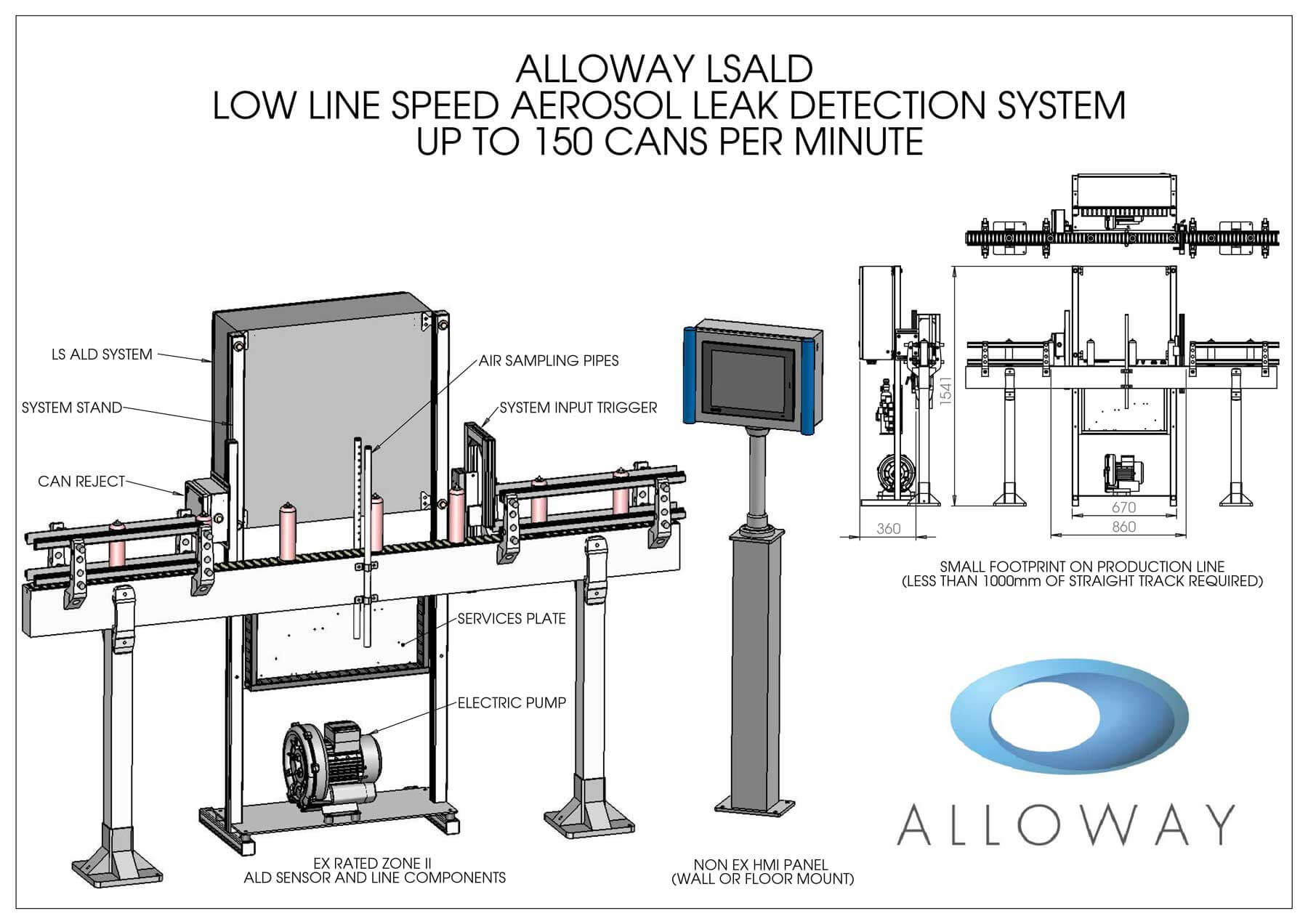

Low Line Speed ALD – Aerosol Micro Leak Detection SystemLow Line Speed ALD – Aerosol Micro Leak Detection System

For Production lines up to 150 cans per min. Aerosol Leak detection system fully compliant with current legislation for identifying and safely removing leaking Aerosol cans from the production line during the manufacturing process.

100% On Line testing, the system is rated for ATEX ExII installation. Meets and exceeds latest testing legislation, Covers Both Standard Micro Leak (8 x 10 -3 mbarls-1) and Water bath Alternative Leak (2 x 10-3 mbarls-1).

Fully modular design enables easy servicing, remote connection for diagnostics and software upgrades. Award winning design. Performance independently assessed and verified.

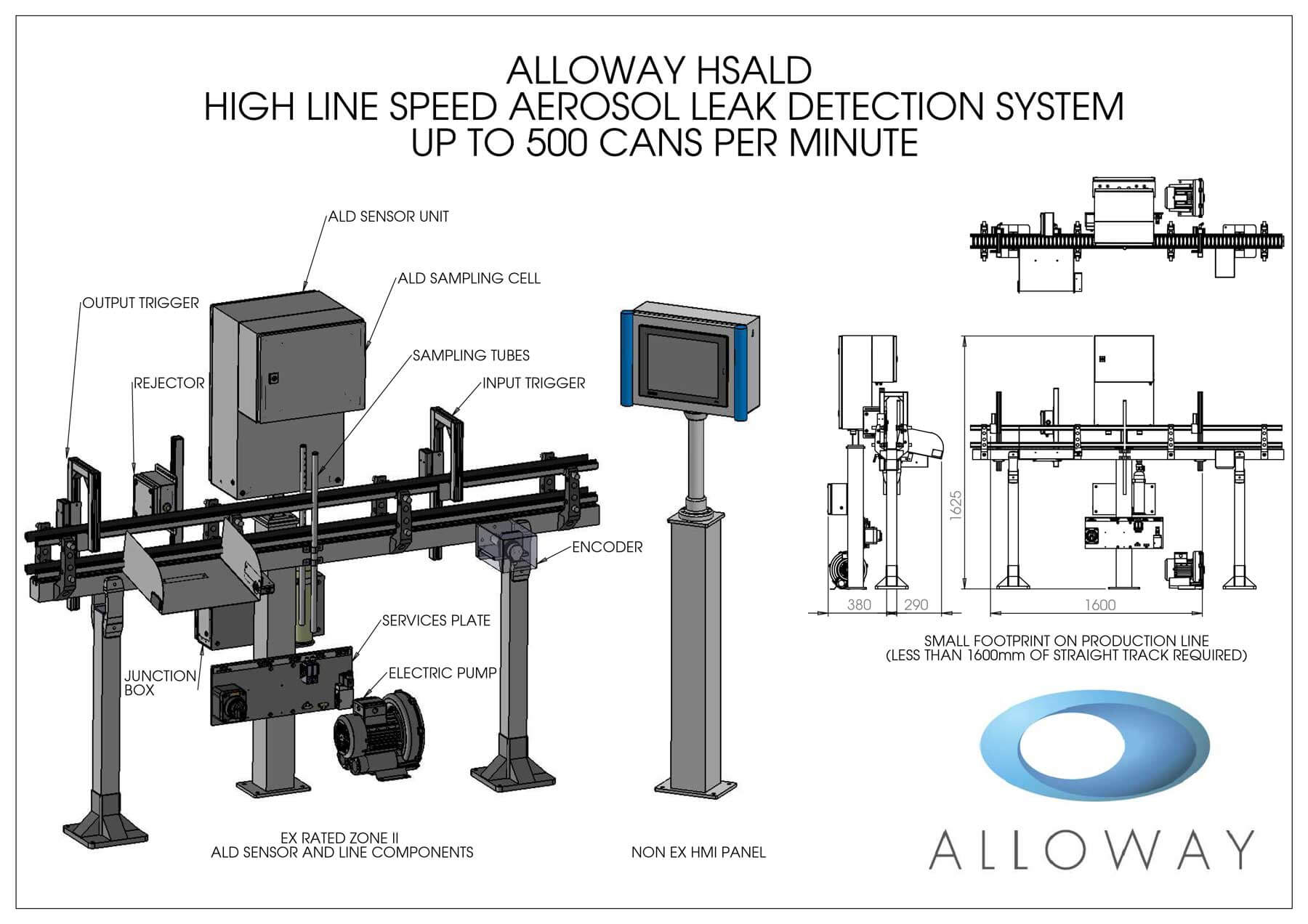

High Line Speed ALD – Aerosol Micro Leak Detections SystemHigh Line Speed ALD – Aerosol Micro Leak Detections System

For Production lines up to 500 cans per min. Aerosol Leak detection system fully compliant with current legislation for identifying and safely removing leaking Aerosol cans from the production line during the manufacturing process.

100% On Line testing, the system is rated for ATEX ExII installation. Meets and exceeds latest testing legislation, Covers Both Standard Micro Leak (8 x 10 -3 mbarls-1) and Water bath Alternative Leak (2 x 10-3 mbarls-1).

Fully modular design enables easy servicing, remote connection for diagnostics and software upgrades. Award winning design. Performance independently assessed and verified.

Aerosol Micro Leak Detection System Verification Unit

This system can be integrated into most Aerosol Microleak Systems. The Microleak Verification unit injects the correct measurement of propellant/air mix to simulate legislated minimum leak rate. The system was designed and manufactured as an alternative to the valve on can leak test.

The operator passes a can into the Microleak system, the gas is automatically injected at the precise time the can passes through the measurement archway and then is rejected from the line. The Microleak Verification then sends a count signal to the customers PLC to indicate that a test has been completed.

The tests are fully repeatable, arcuate and recordable. Digital I/O allows error messaging that can stop the production line until tests are carried out and also provides feedback to quality personnel.

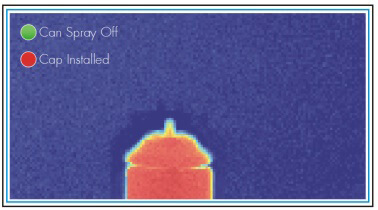

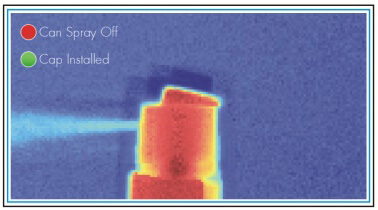

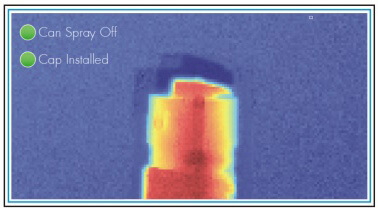

Filled Aerosol Cap and Spray off Verification System

Alloway have designed a vision system that looks for leaking spray off once the cap has been placed on a filled Aerosol can. Additionally the system checks to see if the cap is fitted correctly.

The system will reject faulty containers form the production line. Data logging and signal I/O is available to the customer and can be used as an additional tool by the quality department.

The Alloway Filled Aerosol Cap and Spray off Verification System is an additional quality and safety check and closes the loop on Aerosol Leak Detection.

Cap inspection

Spray off inspection

Quality inspection

Alloway Ltd

Registered Office

10 Alloway Road

Airdrie ML6 8LJ

Design & Manufacture

Unit 37 Wren Court

Strahclyde Business Park

Bellshill ML4 3NQ